- Home

- CommoditiesAluminumSupply ChainSteelSupply Chain

- About Us

- Career

- Blog

- Contact Us

Cathode

Carbon Cathode Block is one of the most important consumables in the aluminum industry, used in the electrolysis process. In this process, by using electric current, the metal aluminum is separated from raw alumina and is placed in the carbon cathode block for aluminum production.

Carbon cathode block is produced in large blocks with dimensions of 55x55x170 centimeters and is made up of a combination of graphite and the highest percentage of carbon. The carbon cathode block must have high resistance to electric current, heat, and other chemical conditions and must be able to absorb aluminum metal well.

In the electrolysis process, the carbon cathode block is used as one of the important components in aluminum production. In this process, the electric current flows from the anode block to the carbon cathode block, resulting in the production of aluminum metal. As an organic substance, the carbon cathode block is cheaper than other materials used in the electrolysis industry and, due to its high resistance to chemical and heat conditions, is used for a long time. Furthermore, due to its properties such as high resistance and long life, the carbon cathode block is used for other applications.

The carbon cathode block is used as one of the important components in the electrolysis process, and its main goal is to absorb oxygen from the electrolyte and discharge negative ions in the aluminum production process. The carbon cathode block is made up of a combination of carbon ribbons, graphite, and metal particles. Additionally, this block should be compatible with the chemical and physical conditions of the electrolyte and have sufficient resistance to heat and electric current.

The carbon cathode acts as a negative electron source in the electrolysis process, absorbing positive electron ions from the molten aluminum to eventually produce aluminum metal.

KTP was founded in 2008 and has been instrumental in the development of minerals trading throughout the world. KTP has since expanded its expertise to a wide variety of commodities and participates in various diversified businesses.

Contact Us

(+98) 220 16992

(+98) 220 54939

(+98) 220 54938

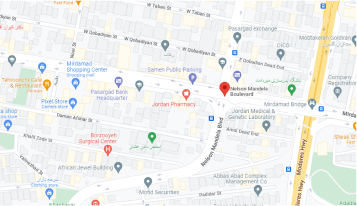

Find Us

- Address : No. 17, GolAzin Boulevard Nelson Mandela St. Tehran, Iran