- Home

- CommoditiesAluminumSupply ChainSteelSupply Chain

- About Us

- Career

- Blog

- Contact Us

Coal Tar Pitch

Coal tar pitch is one of the by-products obtained from the process of producing petroleum coke (a type of coal). Coal tar pitch is essentially formed by the connection of high molecular weight molecules obtained from oil, gas, and the process of coking coal. This substance is a black, thick liquid with a distinct odor.

In the aluminum industry, coal tar pitch is used as a pre-mixed material that is combined with bauxite powder and other raw materials for aluminum production. This material is used as a carbon acceptor in the aluminum production process, acts as an anti-carbonation agent, and separates carbon from aluminum. Additionally, due to its anti-wear, heat-resistant, and water-resistant properties, coal tar pitch is used in the production of heavy-duty boards, prominent facades, port terminals, and oil infrastructure. It is also used as one of the raw materials for producing anti-corrosion coatings in the metal industry and in the production of rubber.

In the process of producing coal tar pitch, first, to separate the pitch from the oil, the petroleum materials are separated from each other by the distillation process. Then, these petroleum materials are subjected to high pressure and high-temperature (between 300-500 degrees Celsius) with various catalysts such as sulfuric acid, heavy metals, or alumina, under chemical reaction. In this process, the petroleum materials are decomposed, and coal tar pitch is obtained as the final product.

The applications of coal tar pitch in the aluminum industry include its use as one of the organic materials in the production process of black carbon. Additionally, it is used in the production of aluminum oxidation anodes. Coal tar pitch, as one of the soft and elastic materials, is used in the production of waterproof and surface protectant materials, such as waterproofing and insulating products. It is also used in the production of various adhesives.

KTP was founded in 2008 and has been instrumental in the development of minerals trading throughout the world. KTP has since expanded its expertise to a wide variety of commodities and participates in various diversified businesses.

Contact Us

(+98) 220 16992

(+98) 220 54939

(+98) 220 54938

Find Us

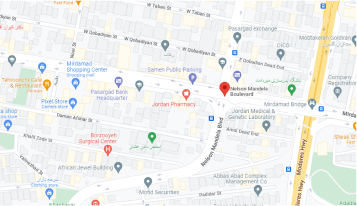

- Address : No. 17, GolAzin Boulevard Nelson Mandela St. Tehran, Iran